What Is Phosphorescent Printing?

Phosphorescent Printing Services is an innovative service that combines luminous materials and printing technology to provide unique visual effects and functional solutions for brands, industrial signs, packaging and other fields. The core of luminous printing lies in the luminous properties of its materials, which can continuously emit light through stored light energy even in low-light or no-light environments, thus achieving eye-catching visual effects. This technology is not only decorative, but also practical and durable, and is widely used in many industries such as clothing, signs, packaging, etc.

Principles and Technology of Luminous Printing

The core technology of luminous printing is Screen Printing (screen printing Technology). Through high-precision screen templates and controllable scraper pressure, luminous inks can achieve layered penetration, forming highly saturated graphics and solid color blocks on the surfaces of different materials. The advantage of screen printing is its wide compatibility with materials, including cotton, synthetic fibers, metals and plastics, which makes luminous printing adaptable to various application scenarios.

The key to luminous printing is the use of luminous inks. This ink absorbs light energy and releases the stored energy in the dark, thereby achieving a continuous luminous effect. Unlike ordinary inks, luminous inks need to be pre-exposed to specific light (such as UV light) to ensure the durability of their luminous effect. Through precise printing processes, luminous printing can provide clear color definition, excellent hiding power, and industrial-grade washability, making it durable in commercial applications.

Application scenarios of luminous printing

Branded clothing

The application of luminous printing is particularly prominent in the field of clothing. By printing luminous patterns on products such as T-shirts, hats, backpacks, etc., brands can create unique visual effects and attract consumers' attention. This technology not only improves the aesthetics of the product, but also enhances its functionality, such as providing higher visibility at night or in low-light environments.

Industrial signs

In the industrial field, luminous printing is widely used for signs, warning signs, and safety signs. These signs can provide clear guidance at night or in emergency situations, thereby improving safety and efficiency. The durability and high contrast of luminous printing make it an ideal choice for industrial signs.

Packaging design

Luminous printing also shows great potential in packaging design. By printing luminous patterns on packaging, brands can attract consumers' attention, especially at night or in low-light environments. This technology can enhance the visual appeal of products while enhancing the brand's market competitiveness.

Decoration and Art

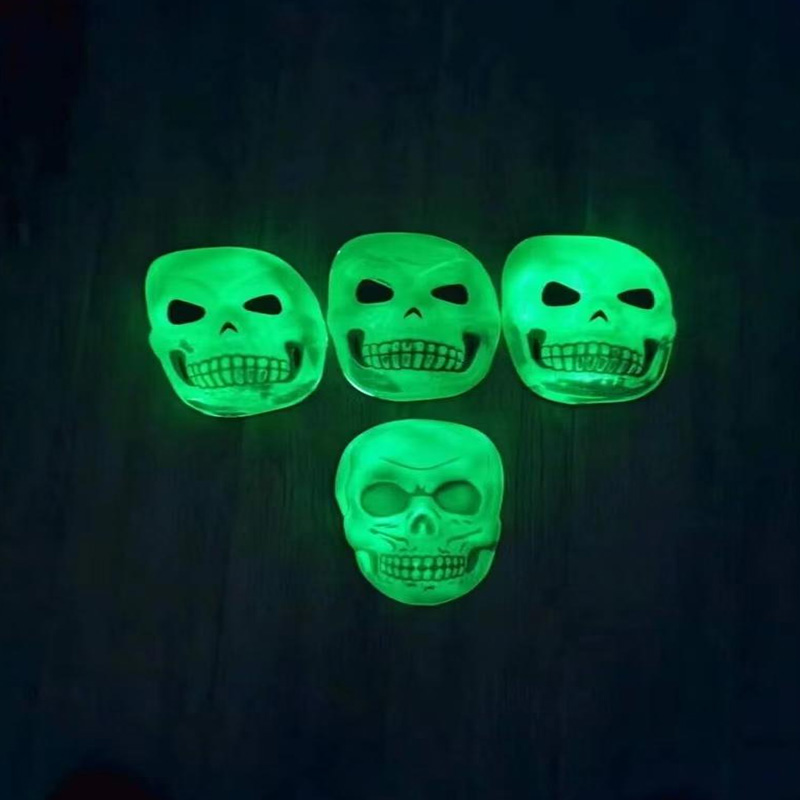

Luminous printing is also widely used in the fields of decoration and art. Whether it is home decorations, artworks or exhibition design, luminous printing can add unique visual effects to these works, making them glow in the dark.

Technical advantages of luminous printing

High precision and high saturation

Through screen printing technology, luminous printing can achieve high-precision pattern production and high-saturation color performance. This technology ensures the clarity and visual impact of the pattern.

Wide range of material compatibility

Luminous printing is suitable for a variety of materials, including cotton, synthetic fibers, metals and plastics. This wide compatibility makes luminous printing adaptable to various application scenarios.

Industrial-grade durability

The luminous printing pattern has excellent washability and durability, and can maintain its luminous effect even after repeated washing or long-term use. This feature makes it have long-term practicality in commercial applications.

Environmental protection and sustainability

With the improvement of environmental awareness, luminous printing technology is also being optimized, using more environmentally friendly inks and materials. This sustainable development direction makes luminous printing also show great potential in the field of environmental protection.

Summary

phosphorescent printing can provide unique visual effects and functional solutions for fields such as branding, industrial identification and packaging design. Its high precision, high saturation, wide material compatibility and industrial-grade durability make it an important part of modern printing technology. With the continuous development of technology, luminous printing will show its unique advantages and potential in more fields, bringing more innovations and possibilities to the market.